Did you know that Washington established the first grade standards in the nation for apples? In 1915, the state started categorizing apples by quality, including color, shape, sugar level, crispness, and condition. Eight years later, the US Department of Agriculture followed suit. National grade standards for apples were introduced in 1923.

Between Washington and US standards, there are six grades of apples:

- Washington Extra Fancy

- US Extra Fancy

- Washington Fancy

- US Fancy

- US No. 1

- US No. 1 Hail

Washington apple growers hold themselves to a higher standard, and exceed even stringent US regulations. Apples are tested at random before and after harvest to ensure the highest quality.

SEE WHY WASHINGTON

HIGHER STANDARDS MEAN BETTER APPLES

One major difference between Washington and US grades on red apple varieties is the definition and interpretation of “good shade of red.” Washington grades require a more uniform, more intense, deeper shade of red than the US grades.

On green and yellow varieties, Washington grades allow for fewer surface blemishes, such as limb rubs, hail damage, and russeting, a discoloration of the apple skin usually caused by weather.

All Washington apples have to meet the toughest internal quality standards in the industry.

WASHINGTON APPLES ARE AN IDEAL SIZE

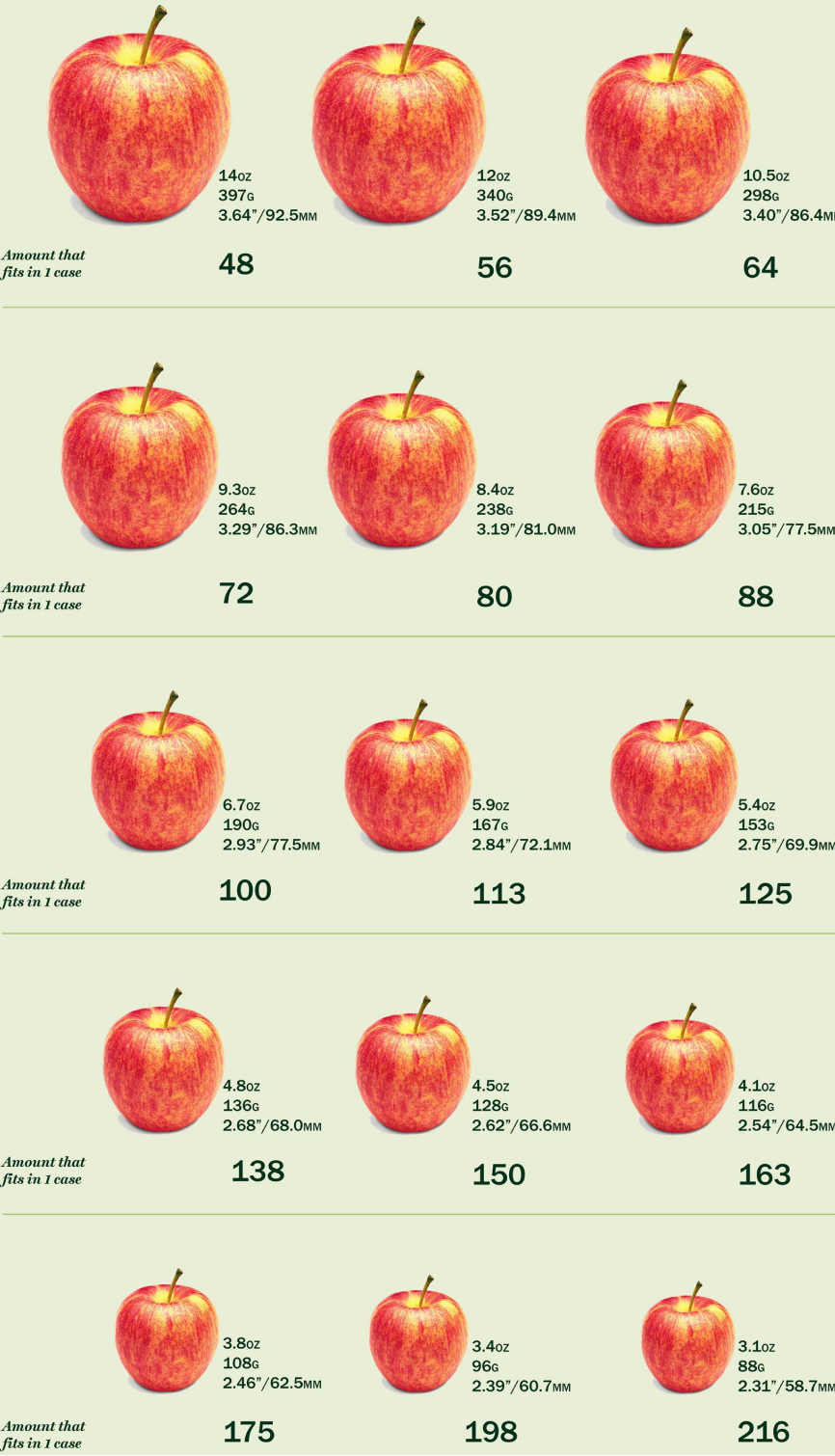

Apple sizing is designated by count — the number of apples that can be packed in a 40-pound fiberboard carton. The largest packed size is 48, which means there are 48 apples in a box. That’s a huge piece of fruit! Supplies of that size are typically very limited.

Washington crops traditionally peak on sizes 88 – 100, which means they’re around 3 inches in diameter, and between 6 – 8 ounces.

APPLE SIZES AT A GLANCE

THE SAME HIGH QUALITY AT HARVEST IS DELIVERED TO CONSUMERS

Once each and every apple is carefully picked in the orchard, the apples are collected into large bins which are promptly brought to a nearby packing house. There, they are thoroughly washed, and computer-controlled cameras and scales weigh, inspect, and separate the apples according to color, shape and size. Another system is able to determine the internal condition of the apple, and to cull apples out that do not meet the high Washington standards for crispness and condition.

The apples are also tested for starch and sugar content to determine when they will be at the peak of flavor. The apples highest in sugar are placed in refrigerated storage rooms and will be packed and sold soonest. Those with higher starch content are stored in sealed, controlled atmosphere (CA) storage rooms, where oxygen is replaced by nitrogen and the temperature is held at about 32 degrees Fahrenheit. This CA storage slows the apples’ respiration rate so that they do not mature as quickly, which helps to maintain crispness and flavor. During this time, the starch also slowly changes to sugar, so that an apple coming out of CA storage has that “just-picked” taste.

Apples ready for shipping are carefully packed by hand into consumer pack or tray pack boxes ready to deliver to grocery stores, fruit markets, and restaurants around the world.